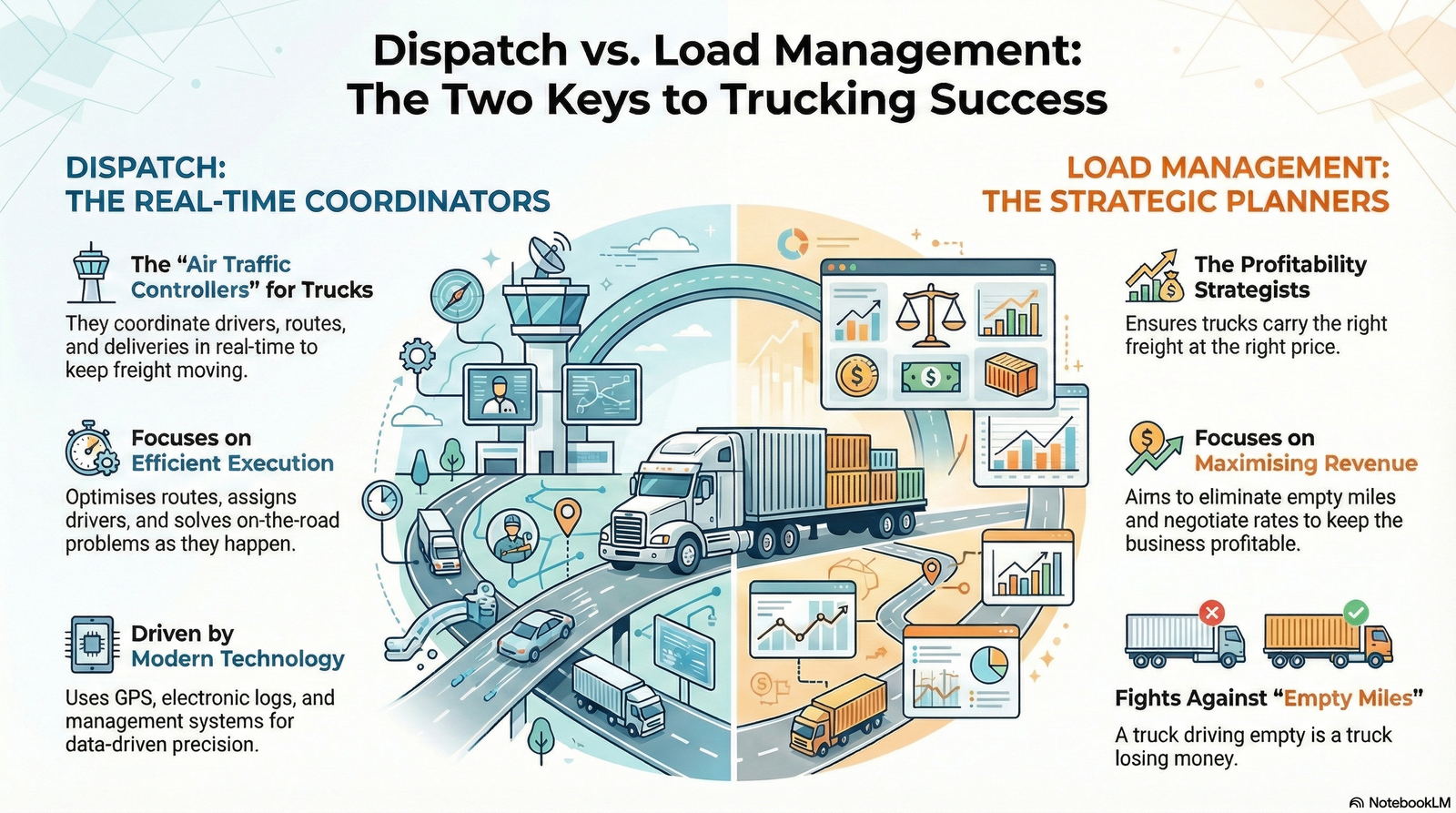

If you're in the trucking business, you know that empty space in your trailers equals empty pockets. That's where load management comes in, the strategic approach to maximizing every inch of trailer space while keeping costs down and profits up. Whether you're running a fleet, working as a freight broker, or trying to understand logistics better, mastering load management is the difference between thriving and just surviving in the freight industry.

What Is Load Management?

Load management is the process of planning, organizing, and optimizing freight shipments to maximize truck capacity, reduce transportation costs, and improve delivery efficiency. It's about putting the right cargo on the right truck at the right time while minimizing wasted space and empty miles.

Think of it as a high-stakes game of Tetris where every decision impacts your bottom line. Good load management means fuller trucks, fewer trips, lower fuel costs, and happier customers.

Key Components of Effective Load Management

Load Planning and Optimization - This starts before any freight touches a trailer. You're analyzing shipment characteristics like weight, dimensions, fragility, and special requirements. You're determining which loads combine well together for multi-stop deliveries. You're balancing weight distribution to prevent damage and ensure safe handling. Smart planning prevents costly mistakes like overweight violations or damaged goods.

Capacity Utilization - This is where you maximize your trailer space. Every cubic foot matters. You're calculating weight-to-space ratios for different freight types, stacking and positioning cargo strategically, combining partial loads when possible, and using the right equipment for the freight type. The goal is getting as close to 100% capacity as safely possible on every trip.

Route Optimization - Load management and route planning go hand-in-hand. You're sequencing multi-stop deliveries to minimize backtracking, planning return loads to eliminate empty backhauls, considering delivery time windows and restrictions, and factoring in fuel costs versus time savings. A well-planned route with optimized loads can cut operating costs by 15-20%.

Load Matching and Tendering - Finding the right freight for available trucks requires strategy. You're matching available cargo with truck location and availability, working with freight brokers to fill capacity gaps, using load boards to find spot market opportunities, and negotiating rates that make economic sense. This is where relationships and market knowledge pay off.

Technology Integration - Modern load management relies on software tools. Transportation management systems (TMS) help optimize load assignments, 3D load planning software visualizes how cargo fits, real-time tracking systems monitor shipment progress, and data analytics identify patterns and improvement opportunities.

Load Management Best Practices

Plan Ahead - Don't wait until the last minute. Advanced planning gives you more options for consolidating shipments, optimizing routes, and negotiating better rates.

Use Technology Wisely - Invest in TMS and load planning software that matches your operation size. These tools pay for themselves quickly through improved efficiency and fewer mistakes.

Track Key Metrics - Monitor capacity utilization rates, deadhead mile percentages, revenue per mile, on-time delivery rates, and cost per shipment. Data reveals opportunities you might otherwise miss.

Build Strong Relationships - Good relationships with shippers, brokers, and drivers create opportunities for better loads and more flexible arrangements. People prefer working with partners they trust.

Cross-Train Your Team - Make sure multiple people understand load planning and optimization. This prevents bottlenecks when someone is unavailable and improves overall operational knowledge.

Communicate Clearly - Keep drivers, customers, and partners informed about load details, timing, and any changes. Clear communication prevents expensive misunderstandings.

Stay Flexible - Have backup plans for common disruptions. When loads change or delays occur, quick adaptation minimizes the impact on your operations.

Load Management Strategies for Different Operation Types

Full Truckload (FTL) Operations - Focus on maximizing weight and cube utilization, finding profitable backhauls, and building dedicated lanes with consistent volume.

Less Than Truckload (LTL) Operations - Specialize in consolidating multiple shipments, optimizing terminal operations and cross-docking, and managing complex multi-stop routes efficiently.

Intermodal Operations - Coordinate between rail and truck efficiently, optimize container utilization, and manage timing around rail schedules and port operations.

Specialized Freight - Develop expertise in refrigerated, hazardous, or oversized loads where specialized knowledge commands premium rates.

If you're looking to improve your load management, start with an honest assessment of current performance by reviewing your capacity utilization and deadhead percentages. Identify your biggest inefficiencies and opportunities. Then invest in appropriate technology for your operation size and needs. Train your team on load planning best practices and your chosen tools. Establish clear processes for load planning, assignment, and optimization. Monitor results and adjust your approach based on data and feedback.

Even small improvements in load management compound over time, creating significant cost savings and competitive advantages.

Load management isn't just about filling trucks, it's a strategic function that determines your profitability, customer satisfaction, and competitive position. The difference between good and great load management shows up directly on your bottom line. Whether you're hauling full truckloads across the country or managing complex LTL networks, the principles remain the same: maximize capacity, minimize waste, use technology smartly, and continuously improve based on data.

Master load management, and you'll build a more efficient, profitable, and sustainable freight operation that stands out in a crowded market. The trucks on the road might look the same, but what's inside them—and how efficiently they're loaded—tells the real story of operational excellence.

Leave a comment

Your email address will not be published. Required fields are marked *